LF3015MB

LF3015MB

Fiber Laser Cutting Machines

Introduction

In the world of manufacturing, precision, speed, and efficiency are paramount. Fiber laser cutting machines, particularly those of the gantry type, have revolutionized how industries operate, providing unparalleled performance in cutting various materials. This article explores the inner workings of these machines, their benefits, and future prospects.

Understanding Gantry-Type Fiber Laser Cutting Machines

Fiber laser cutting machines utilize amplified light that's channeled through fiber optic cables to generate a laser beam capable of cutting through a range of materials. The gantry type refers to the design where the laser cutting head moves along a bridge or gantry above the material.In gantry-type fiber laser cutting machines, the laser head moves in the X and Y directions along the gantry, while the workpiece remains stationary. This setup ensures high precision and allows for large-scale operations, making it ideal for industries such as automotive, aerospace, and heavy machinery.

Advantages of Gantry-Type Fiber Laser Cutting Machines

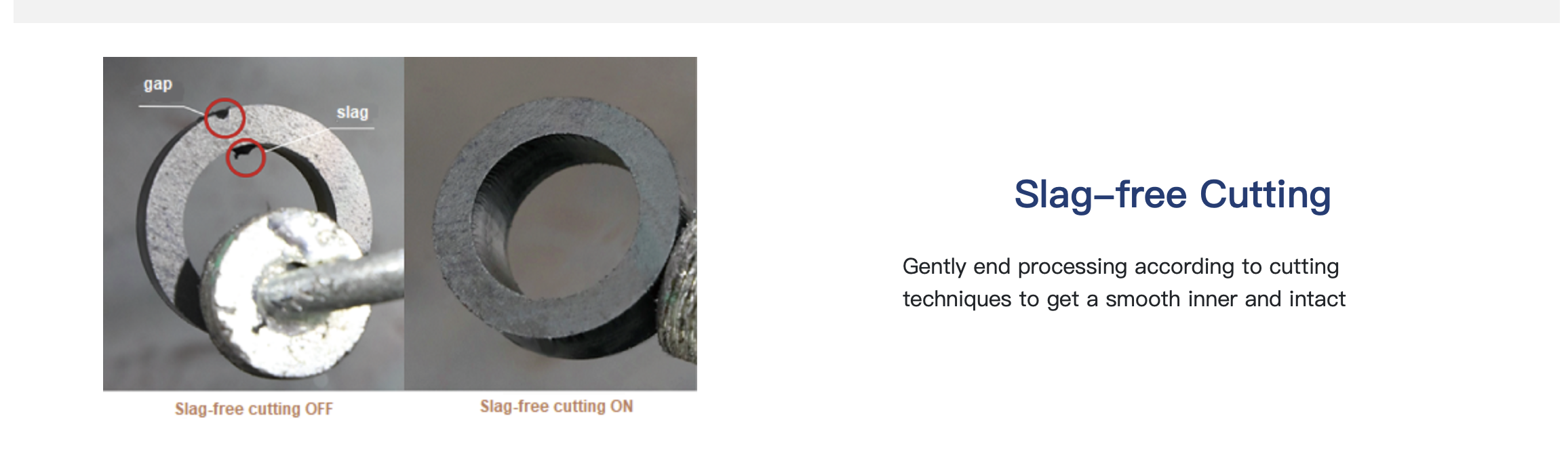

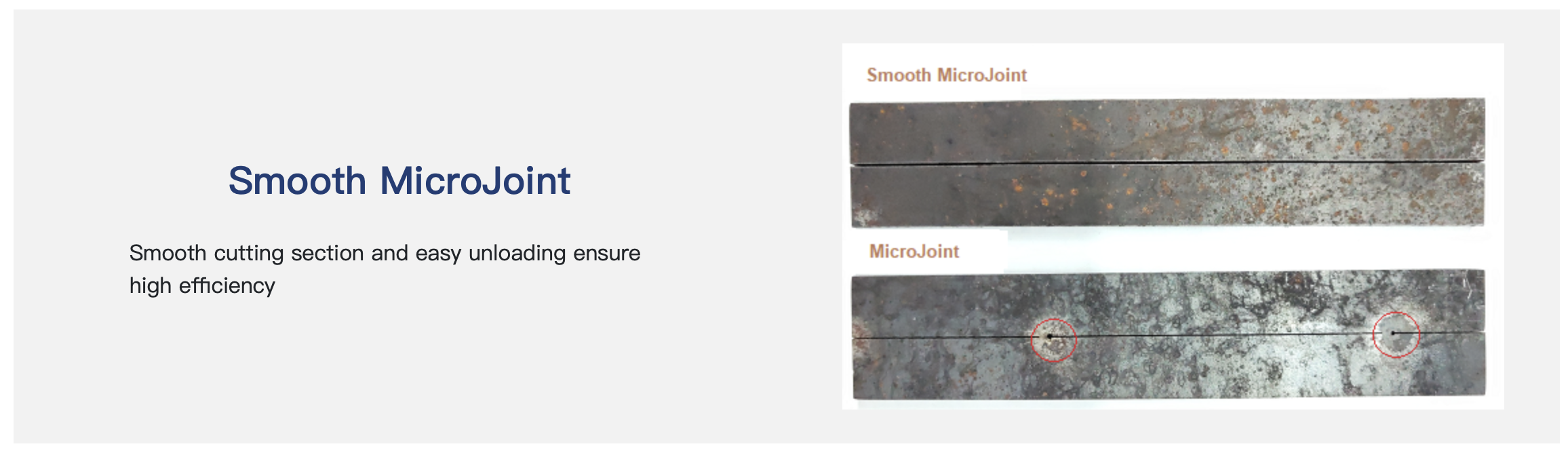

High Precision and Quality

Gantry-type fiber laser cutting machines offer high precision cutting, producing clean, burr-free edges that require little to no finishing work. This increased accuracy reduces the need for additional processing, saving time and resources.

Versatility

These machines are capable of cutting a wide range of materials, including stainless steel, carbon steel, aluminum, and other metal alloys. They can also handle varying material thicknesses, making them extremely versatile in manufacturing settings.

Efficiency and Speed

Fiber laser cutting machines operate at high speeds, significantly reducing production time. Additionally, the stationary workpiece design in gantry-type machines minimizes potential errors caused by material movement, enhancing overall efficiency.

Reduced Maintenance

Compared to other types of laser cutters, fiber lasers require less maintenance as they have fewer moving parts and do not require alignment. This characteristic leads to lower operational costs and less downtime.

Future of Gantry-Type Fiber Laser Cutting Machines

As the industry progresses, so does the technology powering these machines. Future enhancements are likely to focus on speed, precision, and automation. Machine learning and AI could enable these machines to learn from previous operations, optimize cutting paths, and even predict maintenance needs.The industry is also likely to see advancements in software, allowing for more powerful simulation and design capabilities. This feature would allow for better planning and optimization of cutting processes, further enhancing efficiency and reducing waste.

Conclusion

Gantry-type fiber laser cutting machines have transformed the manufacturing landscape with their superior precision, efficiency, and versatility. As technology continues to evolve, these machines will undoubtedly become even more critical to manufacturing processes, driving productivity and innovation to new heights. By embracing these advancements, manufacturers can remain competitive and meet the increasing demand for high-quality, precision-engineered products.

Working Size | |||

X AXIS | 2000 mm | 2500 mm | 3000 mm |

| Y AXIS | 6000 mm | 12000 mm | 24000 mm |

Maximum Speed | ||

XY Speed | 140 | mm/min |

MAXIMUM WORKPIECE WEIGHT |

1050 kg |

LASER POWER 3000 W | ||

Model | 3000 | W |

| Max Thickness | 20 mm | Mild steel |

| 12 mm | STAINLESS STEEL | |

| 12 mm | ALUMINIUM | |

| 5 mm | COPPER | |

| 5 mm | BRASS | |

LASER POWER 6000 W | ||

Model | 6000 | W |

| Max Thickness | 25 mm | Mild steel |

| 20 mm | STAINLESS STEEL | |

| 15 mm | ALUMINIUM | |

| 10 mm | COPPER | |

| 10 mm | BRASS | |

LASER POWER 12000 W | ||

Model | 12000 | W |

| Max Thickness | 30 mm | Mild steel |

| 25 mm | STAINLESS STEEL | |

| 25 mm | ALUMINIUM | |

| 12 mm | COPPER | |

| 12 mm | BRASS | |

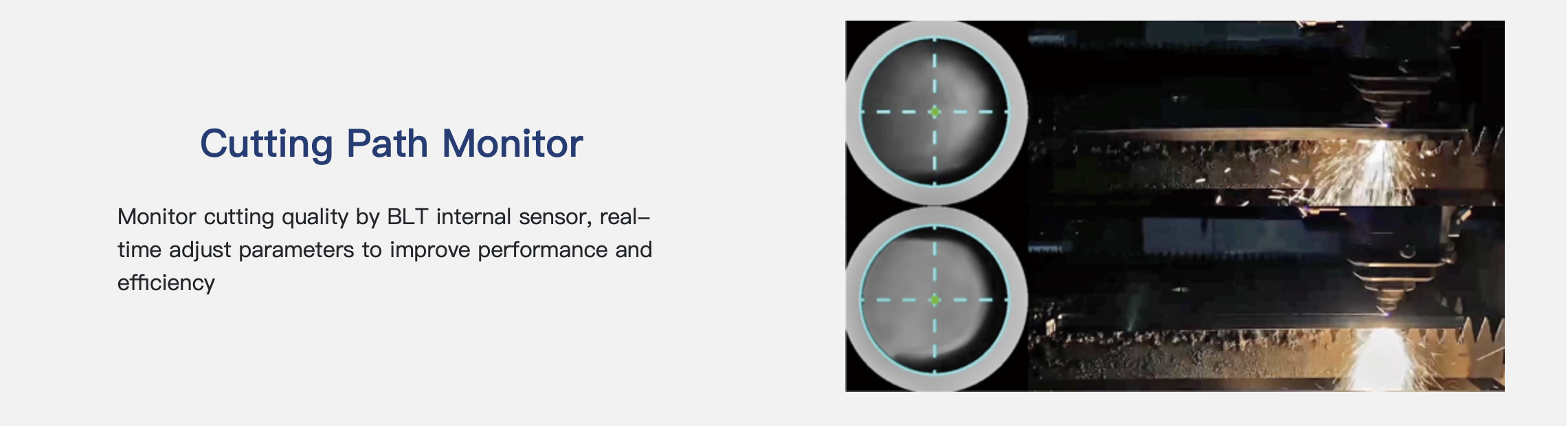

CONTROLLER & SOFTWARE

HypCut is custom software developed for high power laser cutting. Professional high-power laser cutting process is provided, realizing intelligent production. It supports planning and scheduling to assist production management; Its modular design provides users with more concise and efficient operations and helps users complete production quickly.